Maintaining efficiency and reliability in your Milwaukee business’s air compression systems requires careful consideration when replacing or upgrading air compressor parts. Whether you run a manufacturing plant, an auto repair shop, or any operation that depends on consistent compressed air supply, ensuring optimal performance is critical. One of the most common dilemmas business owners face is choosing between OEM air compressor parts and aftermarket compressor components. Understanding the differences, benefits, and potential drawbacks of each option can help you make an informed decision that best suits your needs.

Understanding OEM Air Compressor Parts

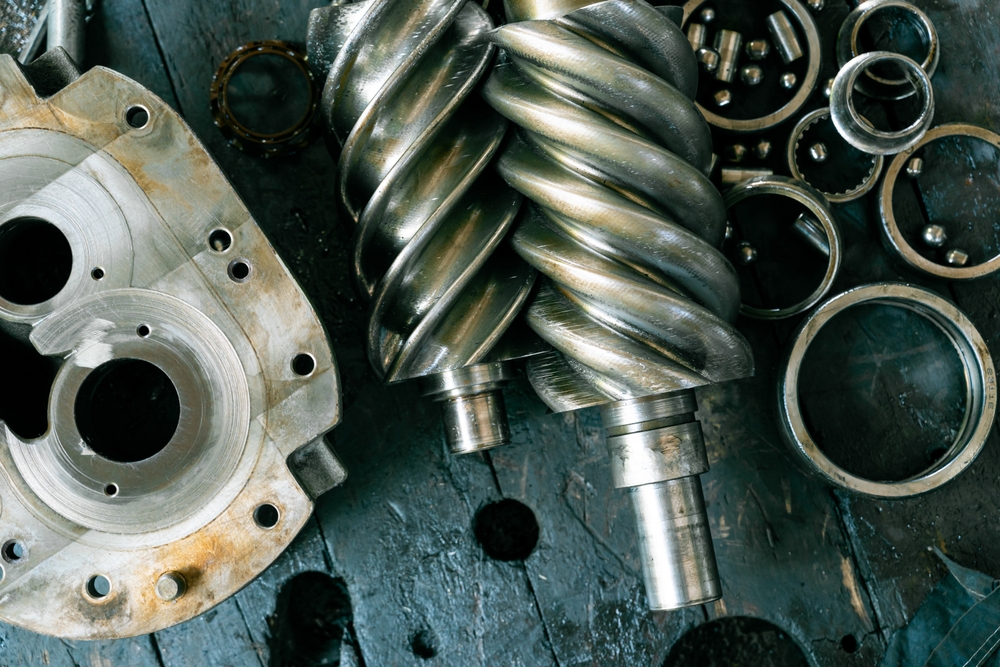

OEM air compressor parts, or Original Equipment Manufacturer parts, are produced by the same company that built your air compressor. These parts are specifically designed to fit and function seamlessly with your equipment. Since they come directly from the manufacturer, you can expect precise specifications, guaranteed compatibility, and compliance with industry standards.

One of the biggest advantages of OEM air compressor parts is reliability. Because they are designed by the original manufacturer, they undergo extensive testing to ensure they meet strict performance and durability standards. This means that when you install an OEM part, you can trust that it will function as intended and maintain the integrity of your air compressor system. Additionally, using OEM parts typically preserves any existing warranties on your equipment, offering further financial protection in case of future issues.

However, there are some downsides to choosing OEM parts. One of the most common concerns among Milwaukee business owners is cost. Since these parts are manufactured and branded by the original company, they often come at a premium price. Availability can also be a concern, especially if your air compressor model is older or if the manufacturer has limited distribution channels. Despite these potential drawbacks, the assurance of quality and compatibility makes OEM air compressor parts a preferred choice for businesses prioritizing longevity and performance.

The Appeal of Aftermarket Compressor Components

Aftermarket compressor components are parts made by third-party manufacturers rather than the original equipment manufacturer. These companies produce compatible parts designed to fit various compressor models, often at a lower cost than OEM options. Many business owners turn to aftermarket solutions when they need a more budget-friendly alternative without compromising too much on quality.

One of the key benefits of aftermarket compressor components is affordability. Because multiple manufacturers produce these parts, competition helps drive prices down. This makes aftermarket options particularly attractive for businesses looking to reduce maintenance costs while still keeping their equipment running smoothly. In some cases, aftermarket manufacturers even improve upon the original design, offering parts that enhance performance or extend the lifespan of your compressor.

Availability is another advantage of aftermarket parts. Since they are produced by various manufacturers, they tend to be more widely available than OEM components, reducing downtime when urgent repairs are needed. Some aftermarket manufacturers also specialize in producing parts for older compressor models that OEM manufacturers no longer support, making them a crucial resource for businesses with legacy equipment.

Despite these benefits, aftermarket compressor components come with risks. Because they are not made by the original manufacturer, there may be variations in quality and performance. Not all aftermarket parts meet the same rigorous testing standards as OEM components, meaning that some may wear out faster or cause compatibility issues. Furthermore, using aftermarket parts may void your compressor’s warranty, which can be a significant concern for businesses relying on manufacturer-backed coverage.

Performance and Longevity Considerations

When evaluating whether to choose OEM air compressor parts or aftermarket compressor components, performance and longevity should be top considerations. Air compressors are vital to many Milwaukee businesses, and ensuring their reliable operation is essential for productivity and cost efficiency.

OEM parts generally provide a higher level of reliability due to their precise engineering and manufacturer testing. They are designed to work in perfect harmony with the existing system, minimizing the risk of malfunctions or premature wear. This makes OEM parts the ideal choice for businesses that depend on uninterrupted operations, where even minor equipment failures can lead to costly downtime.

Aftermarket parts, on the other hand, can vary in quality. While some third-party manufacturers produce high-quality components that match or even exceed OEM standards, others may cut corners to reduce costs. This inconsistency means businesses must carefully vet aftermarket suppliers before purchasing replacement parts. A well-researched purchase from a reputable aftermarket manufacturer can result in a cost-effective solution that does not compromise performance. However, opting for a low-cost, low-quality component could lead to frequent breakdowns, reduced compressor lifespan, and unexpected repair expenses.

For businesses that prioritize long-term investment and stability, OEM air compressor parts remain the safest choice. However, if cost savings and part availability are more pressing concerns, high-quality aftermarket compressor components can still be a viable option, provided they are sourced from reputable suppliers.

Cost-Benefit Analysis for Milwaukee Businesses

For businesses operating in Milwaukee, the decision between OEM and aftermarket air compressor parts should involve a cost-benefit analysis based on specific needs, budget constraints, and long-term goals.

OEM parts, while more expensive, offer peace of mind, especially for businesses that operate high-demand environments where reliability is critical. The guaranteed quality and compatibility reduce risks associated with equipment failure, making them a worthwhile investment for companies that cannot afford unplanned downtime. Additionally, preserving manufacturer warranties with OEM components can save businesses from costly repairs in the long run.

Aftermarket compressor components, on the other hand, provide an opportunity for cost savings, especially for businesses that require frequent part replacements. If sourced from a trusted manufacturer, aftermarket parts can perform just as well as OEM components without the premium price tag. For businesses that operate on a tighter budget, carefully selecting high-quality aftermarket parts can help balance cost and performance.

Another important factor to consider is the availability of technical support and service. OEM manufacturers typically offer customer support and troubleshooting assistance when using their components, whereas aftermarket suppliers may not always provide the same level of service. Milwaukee businesses that rely on local suppliers for air compressor parts may find it beneficial to choose a provider that offers technical guidance, whether they opt for OEM or aftermarket parts.

Making the Right Choice for Your Business

Ultimately, the decision between OEM air compressor parts and aftermarket compressor components depends on the unique needs of your Milwaukee business. If reliability, warranty protection, and long-term performance are your top priorities, OEM parts are the best choice. They ensure seamless integration, optimal performance, and compliance with industry standards, reducing the likelihood of unexpected issues.

However, if cost savings and availability are more critical to your operations, high-quality aftermarket parts from reputable manufacturers can be a smart alternative. By carefully selecting aftermarket suppliers and ensuring the parts meet necessary quality standards, businesses can achieve a balance between affordability and performance.

Conclusion

In the end, understanding the trade-offs between OEM and aftermarket air compressor parts enables Milwaukee businesses to make informed decisions that align with their operational goals. Whether choosing OEM for peace of mind or aftermarket for cost-effective solutions, ensuring the continued efficiency and reliability of your air compressor system is key to maintaining productivity and success.

Need an Air Compressor Store in Milwaukee, WI?

Established in 1932, Wenniger Compressor Co. specializes in air compressors, centrifugal pumps, diaphragm metering pumps, fans, generators, high-pressure air compressors, hoists (all types), lubricated reciprocating air compressors, oil separators, refrigerated air compressor dryers, rotary screw, sliding vane air compressors, submersible pumps, and vacuum pumps. Additional services include rental units, parts, lubricants, rotary screw compressors, service calls, routine maintenance, and much more. Our employees are all licensed to help you make the best decision. Contact us today to schedule an appointment or to get an estimate on the perfect service you need.