Air compressors are indispensable in various industries, powering tools and equipment that ensure smooth operations. Over time, the performance of an air compressor can decline due to wear and tear, particularly in its air end—the heart of the machine. In this blog, we’ll delve into the benefits of air end rebuilds.

Understanding the Role of the Air End in Your Compressor

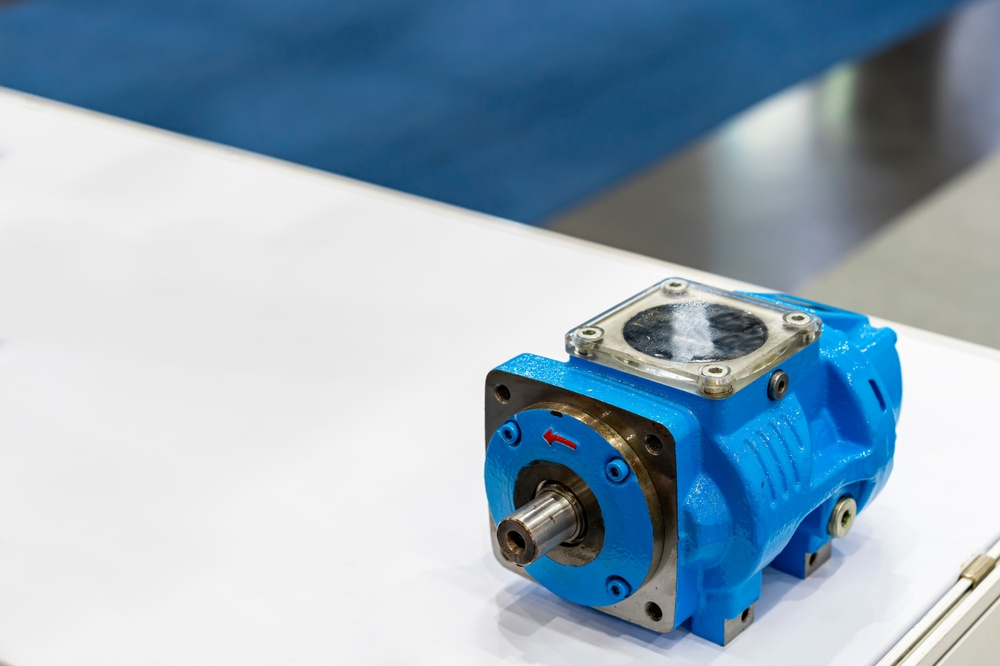

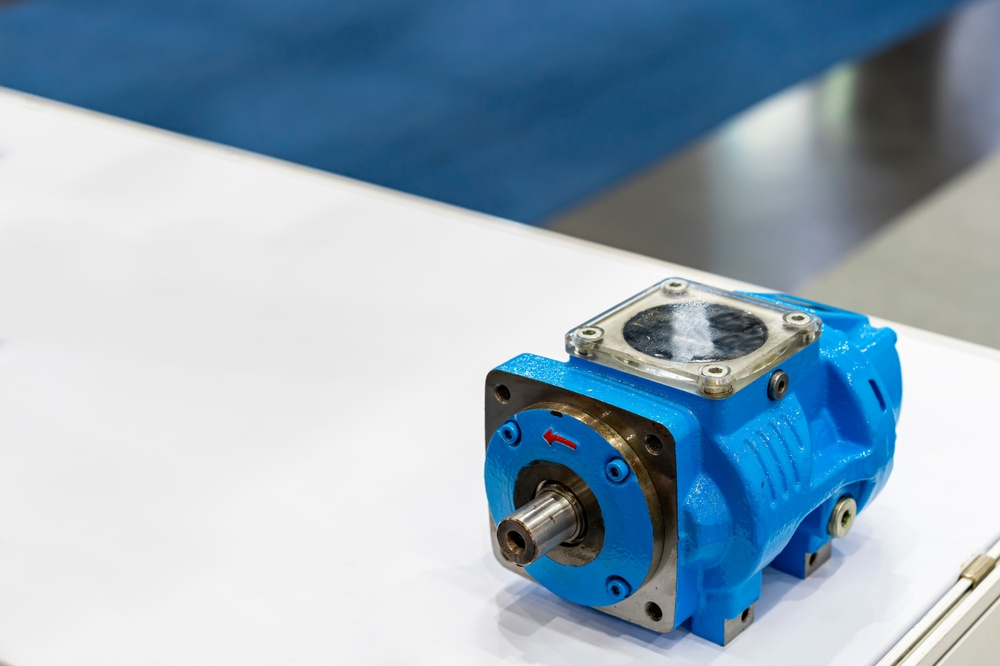

The air end is the component in an air compressor where air is compressed. It consists of rotors, bearings, and seals, all of which are subjected to immense pressure and temperature fluctuations during operation. With time, these parts degrade, leading to reduced efficiency and potential downtime.

Instead of replacing the entire compressor, an air end rebuild can restore its performance while saving money and resources.

Why Opt for an Air End Rebuild?

1. Cost-Effective Alternative

Investing in an air compressor rebuild service is significantly less expensive than purchasing a brand-new unit. In regions like Milwaukee and Wisconsin, where industrial operations rely heavily on air compressors, air end rebuilds offer a budget-friendly solution to maintain functionality without breaking the bank.

2. Extending Equipment Lifespan

An air end rebuild rejuvenates critical components, effectively adding years to the compressor’s operational life. This ensures your investment yields maximum returns while avoiding premature replacements.

3. Enhanced Efficiency

A worn-out air end can lead to increased energy consumption and inconsistent performance. By rebuilding the air end, your air compressor regains its efficiency, ensuring optimal output and reduced energy costs.

Key Indicators Your Air Compressor Needs an Air End Rebuild

Knowing when to seek an air compressor rebuild service is vital to prevent unexpected breakdowns. Here are the signs:

- Increased Noise Levels: Abnormal sounds often indicate wear in bearings or rotors.

- Higher Energy Bills: Declining efficiency results in more power consumption.

- Reduced Air Output: A drop in performance is a clear sign of wear.

- Oil Leaks or Contamination: Damaged seals can lead to oil issues, affecting performance.

If you notice any of these signs, it’s time to consider an air end rebuild Milwaukee or consult a reliable air compressor repair Wisconsin provider.

The Process of Air End Rebuilds

Understanding what happens during an air end rebuild can help you appreciate its value.

Inspection and Diagnosis

Experts start by disassembling the air end to inspect internal components. They assess the wear and identify parts that require repair or replacement.

Replacement of Worn Components

Key components like bearings, seals, and gaskets are replaced with high-quality parts. This ensures the rebuild is as close to new as possible.

Reassembly and Testing

After replacing worn parts, technicians reassemble the air end with precision and test the compressor under load conditions to verify its performance.

Benefits of Choosing a Professional Air Compressor Rebuild Service

1. Expertise and Experience

Certified technicians specializing in air compressor repair Wisconsin and air end rebuild Milwaukee bring years of experience to the table. They use advanced diagnostic tools to ensure thorough inspections and accurate rebuilds.

2. Customized Solutions

Every compressor has unique requirements based on its application and usage. Professionals provide tailored rebuild solutions, ensuring compatibility and longevity.

3. Warranty Assurance

Reputable services offer warranties on rebuilds, providing peace of mind and guaranteeing the quality of work.

How Air End Rebuilds Support Sustainability

Sustainability is a growing concern for businesses, and air end rebuilds align with eco-friendly practices.

1. Reduced Material Waste

By rebuilding instead of replacing, you minimize the disposal of old compressors and components, reducing industrial waste.

2. Energy Efficiency

Rebuilt compressors operate more efficiently, lowering energy consumption and contributing to a greener environment.

3. Promoting Resource Reuse

Rebuilding allows the reuse of existing materials, supporting the circular economy and reducing demand for new raw materials.

Choosing the Right Service Provider

Selecting a reliable provider for an air end rebuild is crucial to ensure quality and longevity. Here’s what to look for:

1. Local Expertise

Opt for services like air end rebuild Milwaukee or air compressor repair Wisconsin to ensure quick turnaround times and familiarity with regional needs.

2. Reputation and Reviews

Check customer reviews and testimonials to gauge the service quality. A good track record indicates reliability.

3. Certifications and Warranty

Ensure the provider is certified and offers warranties on their rebuild services, showcasing their confidence in the quality of work.

Tips for Maintaining Your Air Compressor After a Rebuild

A successful rebuild is just the beginning. Proper maintenance ensures your compressor remains in top condition for years.

Regular Inspections

Schedule routine inspections to catch wear and tear early.

Lubrication

Use manufacturer-recommended lubricants to reduce friction and prolong the lifespan of components.

Monitor Performance

Track key metrics like air output, energy consumption, and noise levels to detect issues promptly.

Partner with Reliable Repair Services

Work with a trusted air compressor rebuild service provider for ongoing support and maintenance.

Why Milwaukee and Wisconsin Businesses Trust Air End Rebuilds

Industries in Milwaukee and Wisconsin heavily rely on air compressors for daily operations. Services like air end rebuild Milwaukee and air compressor repair Wisconsin cater to diverse industrial needs, from manufacturing to construction. The expertise available in these regions ensures businesses can depend on cost-effective, high-quality rebuild solutions to keep their operations running smoothly.

Final Thoughts

Air end rebuilds offer a practical and cost-effective solution to restore the performance of your air compressor. By opting for professional air compressor rebuild service, you save money, extend the lifespan of your equipment, and contribute to sustainable practices. Whether you’re in Milwaukee or Wisconsin, partnering with trusted providers ensures your air compressor remains a reliable asset for your business.

If your compressor is showing signs of wear, don’t wait for a complete breakdown. Reach out to an expert in air end rebuild Milwaukee or air compressor repair Wisconsin today and experience the benefits of a rejuvenated air compressor!

Need an Air Compressor Store in Milwaukee, WI?

Established in 1932, Wenniger Compressor Co. specializes in air compressors, centrifugal pumps, diaphragm metering pumps, fans, generators, high-pressure air compressors, hoists (all types), lubricated reciprocating air compressors, oil separators, refrigerated air compressor dryers, rotary screw, sliding vane air compressors, submersible pumps, and vacuum pumps. Additional services include rental units, parts, lubricants, rotary screw compressors, service calls, routine maintenance, and much more. Our employees are all licensed to help you make the best decision. Contact us today to schedule an appointment or to get an estimate on the perfect service you need.