In the ever-evolving landscape of industrial machinery, rotary screw compressors have emerged as pivotal components in optimizing efficiency and performance. This guide delves into the core aspects of rotary screw compressors, including their applications, functionality, and benefits. Whether you’re an industry professional or a curious reader, this comprehensive guide will illuminate the crucial role of rotary screw compressors in modern industry.

What Are Rotary Screw Compressors Used For?

Rotary screw compressors are vital in various industrial applications, thanks to their ability to deliver consistent, reliable, and high-quality compressed air. Their primary uses include:

1. Manufacturing

In manufacturing settings, rotary screw compressors provide the necessary compressed air to power pneumatic tools, control systems, and machinery. This ensures smooth operation and efficiency on production lines.

2. Automotive Industry

In the automotive sector, rotary screw compressors are used for tasks such as painting, tire inflation, and powering pneumatic tools. Their reliability and efficiency make them indispensable in automotive repair shops and production facilities.

3. Food and Beverage Industry

The food and beverage industry relies on rotary screw compressors for various processes, including packaging, mixing, and conveying. The compressors ensure that the air used in these processes is clean and free of contaminants, which is critical for maintaining product quality and safety.

4. Pharmaceutical Industry

For the pharmaceutical industry, rotary screw compressors are used to provide clean and dry compressed air for manufacturing and packaging processes. They help maintain stringent hygiene standards and ensure the safety of pharmaceutical products.

5. Construction

In construction, rotary screw compressors are often used to power tools and equipment such as jackhammers, drills, and air brakes. Their portability and efficiency make them ideal for demanding construction environments.

How Do Rotary Screw Compressors Work?

Understanding the operation of rotary screw compressors involves diving into their unique mechanism. Here’s a breakdown of how these machines function:

1. Basic Principle

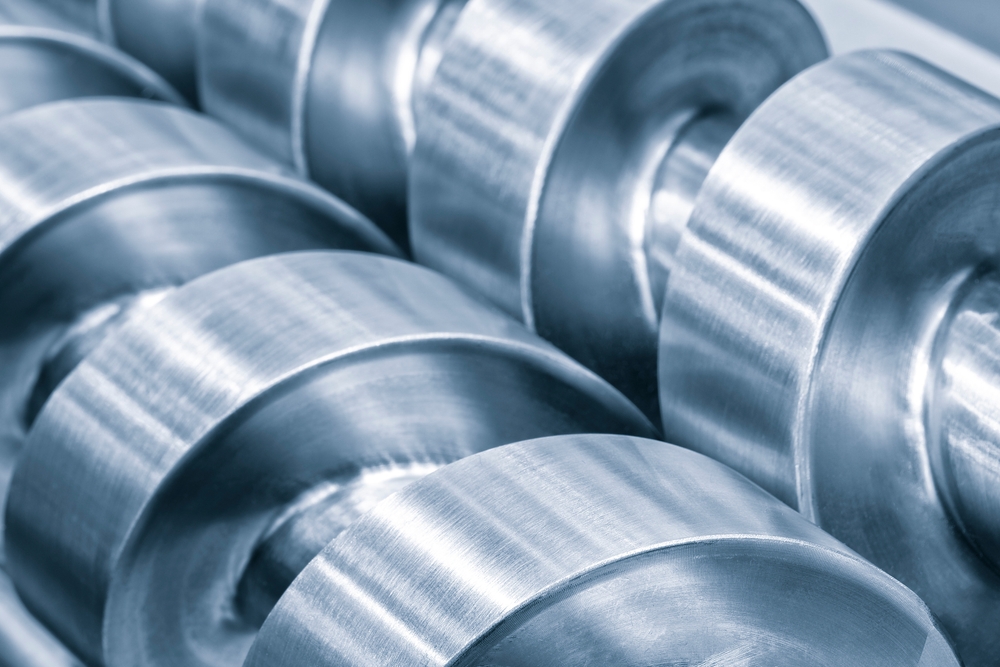

Rotary screw compressors operate on the principle of positive displacement. They utilize two interlocking helical screws (or rotors) to compress air. As the rotors turn, air is trapped between them and the compressor housing, and the volume of this air is reduced, thereby increasing its pressure.

2. Air Intake

The process begins when ambient air enters the compressor through an intake valve. The air is then drawn into the compressor chamber, where it is captured by the rotating screws.

3. Compression

Inside the compressor chamber, the rotating screws push the air along a spiral path. As the screws turn, they compress the air into progressively smaller spaces. This continuous compression process results in the generation of high-pressure air.

4. Discharge

Once the air reaches the desired pressure level, it is discharged from the compressor and directed to the intended application or storage tank. The discharge process is carefully controlled to ensure a steady flow of compressed air.

5. Cooling

During operation, rotary screw compressors generate heat. To manage this, they are equipped with cooling systems—either air-cooled or water-cooled—to dissipate excess heat and maintain optimal operating temperatures.

Benefits of Rotary Screw Compressors

Rotary screw compressors offer numerous advantages over other types of compressors, including:

1. Efficiency

Rotary screw compressors are known for their high efficiency and reliability. They provide a steady supply of compressed air with minimal energy consumption, which can lead to significant cost savings in the long run.

2. Continuous Operation

Unlike some other compressors, rotary screw models are designed for continuous operation. They can run 24/7 without needing frequent shutdowns or maintenance, making them ideal for high-demand industrial applications.

3. Low Noise Levels

Modern rotary screw compressors are engineered to operate quietly, reducing noise pollution in the workplace. This is achieved through advanced design features and sound-dampening technologies.

4. Compact Design

The compact design of rotary screw compressors allows them to fit into smaller spaces, which is particularly beneficial in environments with limited room for equipment.

5. Durability

Built to withstand harsh conditions, rotary screw compressors are durable and capable of handling high workloads. Their robust construction ensures a long operational life and reliable performance.

Choosing the Right Rotary Screw Compressor

Selecting the right rotary screw compressor involves considering several factors:

1. Application Requirements

Evaluate the specific requirements of your application, including the desired air pressure, flow rate, and operational conditions. This will help you choose a compressor that meets your needs effectively.

2. Energy Efficiency

Look for compressors with high energy efficiency ratings. Energy-efficient models can help reduce operational costs and minimize environmental impact.

3. Maintenance Needs

Consider the maintenance requirements of the compressor. Opt for models with easy access to components and those that offer extended service intervals.

4. Noise Levels

If noise is a concern in your working environment, choose a compressor designed for low noise operation.

5. Budget

Balance your budget with the compressor’s features and benefits. Investing in a high-quality rotary screw compressor can lead to long-term savings and improved efficiency.

Conclusion

Rotary screw compressors have revolutionized industrial efficiency by offering reliable, efficient, and continuous compressed air solutions. Their applications span various industries, including manufacturing, automotive, food and beverage, pharmaceutical, and construction. Understanding how rotary screw compressors work and their benefits can help you make informed decisions when selecting and utilizing these essential machines.

Need an Air Compressor Store in Milwaukee, WI?

Established in 1932, Wenniger Compressor Co. specializes in air compressors, centrifugal pumps, diaphragm metering pumps, fans, generators, high-pressure air compressors, hoists (all types), lubricated reciprocating air compressors, oil separators, refrigerated air compressor dryers, rotary screw, sliding vane air compressors, submersible pumps, and vacuum pumps. Additional services include rental units, parts, lubricants, rotary screw compressors, service calls, routine maintenance, and much more. Our employees are all licensed to help you make the best decision. Contact us today to schedule an appointment or to get an estimate on the perfect service you need.