Rotary screw compressors have emerged as indispensable tools in various industrial applications, revolutionizing efficiency and productivity. In this comprehensive guide, we’ll delve into how does a rotary screw compressor work and explore the advantages of using a rotary screw compressor in industrial settings.

Understanding Rotary Screw Compressors

What is a Rotary Screw Compressor?

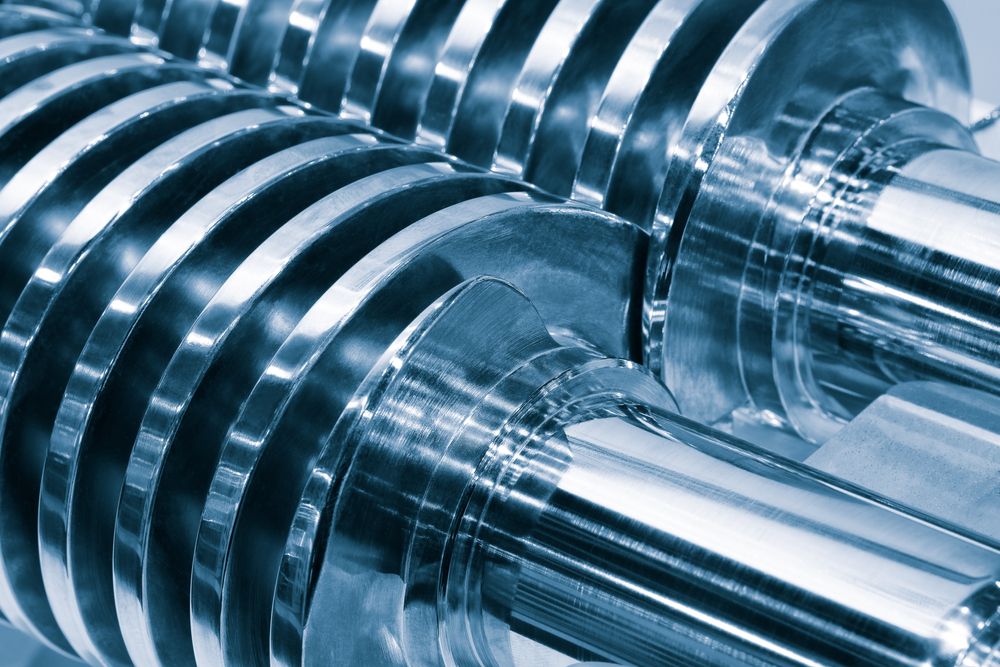

A rotary screw compressor is a type of positive displacement compressor that utilizes rotary screw technology to compress air. Unlike reciprocating compressors, which use pistons to compress air, rotary screw compressors employ twin screws that mesh together to compress air and deliver it at high pressure.

How Does a Rotary Screw Compressor Work?

Compression Process

The compression process in a rotary screw compressor begins when air enters the compressor through an intake valve. Inside the compressor, two helical screws rotate in opposite directions, drawing air into the space between them. As the screws rotate, the air is progressively compressed, increasing its pressure and temperature.

Cooling and Oil Injection

To prevent overheating and lubricate the moving parts, rotary screw compressors employ a cooling and oil injection system. A coolant circulates through the compressor housing, dissipating heat generated during compression. Additionally, oil is injected into the compression chamber to lubricate the screws and create a tight seal, ensuring efficient compression and preventing leakage.

Discharge

Once compressed, the air is discharged from the compressor through a discharge valve, where it is stored in a receiver tank or delivered directly to the application. The compressed air can then be used to power pneumatic tools, operate machinery, or perform various industrial processes.

Advantages of Using a Rotary Screw Compressor

1. High Efficiency

Rotary screw compressors are renowned for their high efficiency and energy-saving capabilities. The continuous rotary motion of the screws results in smooth, vibration-free operation, reducing energy consumption and minimizing maintenance requirements.

2. Continuous Operation

Unlike reciprocating compressors, which may need to stop and start frequently to maintain pressure, rotary screw compressors can operate continuously without interruption. This makes them ideal for applications that require a steady supply of compressed air, such as manufacturing, automotive, and aerospace industries.

3. Compact Design

Rotary screw compressors are typically more compact and lightweight than reciprocating compressors of comparable capacity. Their space-saving design allows for easy installation in confined spaces or mobile applications, making them versatile solutions for a wide range of industrial settings.

4. Low Noise Levels

The rotary motion of the screws in a rotary screw compressor results in quieter operation compared to reciprocating compressors, which can produce loud, intermittent noise. The reduced noise levels of rotary screw compressors make them suitable for use in noise-sensitive environments, such as hospitals, laboratories, and office buildings.

5. Minimal Maintenance

With fewer moving parts and less wear and tear than reciprocating compressors, rotary screw compressors require minimal maintenance. Routine tasks such as oil changes, filter replacements, and inspections are typically straightforward and can be performed quickly, reducing downtime and maintenance costs.

6. Wide Range of Capacities

Rotary screw compressors are available in a wide range of capacities to suit various industrial applications, from small workshops to large manufacturing facilities. Whether you need a compact, portable compressor for on-site use or a high-capacity compressor for industrial production, there’s a rotary screw compressor to meet your needs.

Conclusion

Rotary screw compressors have become indispensable tools in the industrial landscape, thanks to their efficiency, reliability, and versatility. By understanding how does a rotary screw compressor work and the advantages of using a rotary screw compressor, businesses can harness the power of these industrial powerhouses to streamline operations, increase productivity, and achieve greater efficiency. Whether you’re in manufacturing, construction, or automotive industry, a rotary screw compressor can be a valuable asset that drives your business forward.

Need an Air Compressor Store in Milwaukee, WI?

Established in 1932, Wenniger Compressor Co. specializes in air compressors, centrifugal pumps, diaphragm metering pumps, fans, generators, high-pressure air compressors, hoists (all types), lubricated reciprocating air compressors, oil separators, refrigerated air compressor dryers, rotary screw, sliding vane air compressors, submersible pumps, and vacuum pumps. Additional services include rental units, parts, lubricants, rotary screw compressors, service calls, routine maintenance, and much more. Our employees are all licensed to help you make the best decision. Contact us today to schedule an appointment or to get an estimate on the perfect service you need.